humiSonic in the printing industry

Paper manufacturing, storage and printing processes are affected by variations in the water content related to the ambient humidity.

As we know, paper is made from cellulose, that is, from plant fibres that are intrinsically hygroscopic. The water content of paper reaches equilibrium at conditions that depend on the temperature and the relative humidity of the room. For example, at a temperature of 20 °C there may be a water content of 6% by weight with a humidity of 40%. This content may reach 7% for a relative humidity of 60% and even 10% for a relative humidity of 80%.

The variation in water content causes dimensional alterations, in that the sheet of paper contracts when the water content decreases, and expands when the water content increases. Specifically, the variation in the length of plant fibre may fluctuate between 0.1% and 0.2% with a 10% change in humidity. On an A4 sheet this means a difference of around half a millimetre: when working with the typical sheets of 16 pages used by printers the difference may exceed 2 mm.

This phenomenon, in itself negative, as it for example affects the correctness of all cutting and printing operations, does not necessarily occur uniformly.*

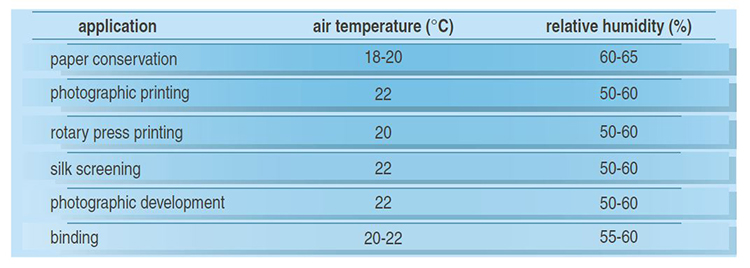

Table - Recommended temperature and humidity values for different types of paper processing*

* "Air humidification" by R. Lazzarin and L.Nalini

Main Benefits

|

|

|

|

|

To limit electrostatic discharges that can damage electronic components. |

Controlling humidity in printing processes avoids breakages and misalignment due to dimensional variations, and optimises ink absorption. |

Maintaining the correct humidity level in work environments increases worker comfort and reduces the proliferation of viruses and bacteria. |

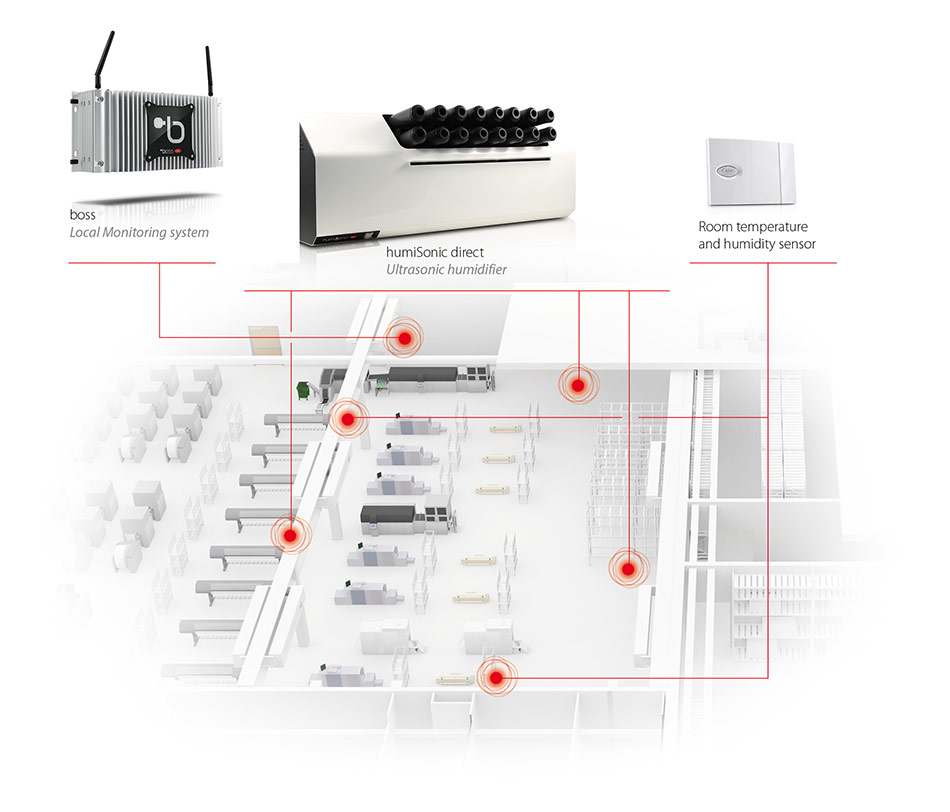

humiSonic direct

humiSonic direct is the new solution for direct room humidification that exploits innovative ultrasound technology.

humiSonic direct incorporates, in just one compact solution, all the components needed for operation, making it the best proposal on the market in terms of ease and flexibility of installation, for both new systems and the retrofit of existing buildings.

CAREL ultrasound technology minimises energy consumption, while at the same time reducing maintenance, thanks to the extraordinary lifespan of the piezoelectric transducers (up to 10,000 h). Hygiene is moreover guaranteed by the use of stainless steel components and automatic washing and filling cycles.

With Modbus compatibility available as standard, humiSonic direct can communicate with any control system, easily integrating with the rest of the installation.